Prototype Design Forms & Steps

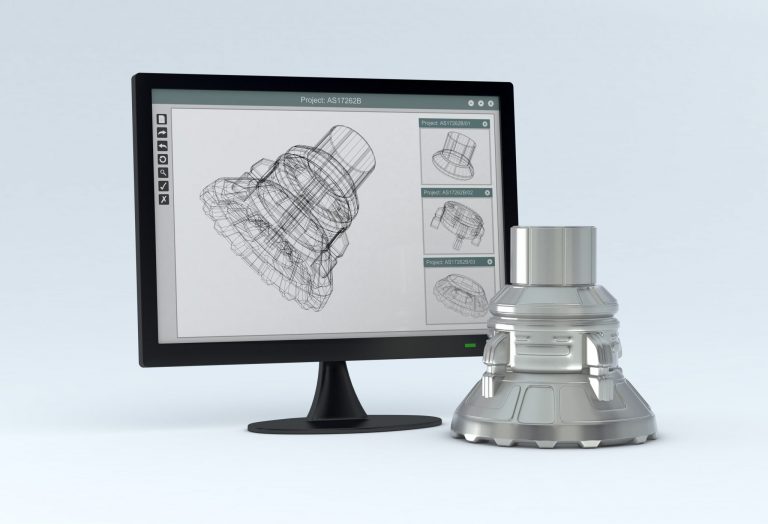

There are several steps in developing a product from an idea, no matter how you prototype a part. One of the first steps is creating a 3D computer-aided design (CAD) model of your concept. The animation of your part from a 2D image on a piece of paper into a 3D model is instrumental in engineering a detailed vision of your part.

The design step is going to be applicable to your prototyping process no matter what material you use. There are 4 rapid prototyping process steps to keep in mind going forward:

- Create a 3D file.

- Get a quote from the production facility.

- Create the prototype (see how this works below).

- Test the part to verify the correctness of the design model.

Rapid Prototyping Design Model

Prototype design is a critical part of the manufacturing process because it provides a detailed look at your new part and allows you to adapt to an issue that may arise during assembly. We’re a prototype design company that can start this process for you or work with a file you have already started. We utilize the most recent software to ensure you’re getting access to the latest technology during this important first step. Manufacturing prototyping can be done in many forms. Contact our team to get started. If you want to learn more about Ston-Engineering specializations, keep reading below.

Injection Molding Process

Injection Molding is a manufacturing process for producing parts by injecting molten resin/plastic material into a mold. This process can be scaled for prototype or production volumes anywhere from 100 parts to 10s of millions of parts. The mold itself is the differentiating factor in prototype injection molding and production injection molding; the injection mold tool (or tooling) is built with an understanding of the estimated annual volume of parts to be produced. High-volume production tools are built from steel and have a single cavity tool or have multiple cavities (4, 16, 64, 128 cavity tools are common).

A prototype injection mold tool — sometimes called bridge tooling or prototype tooling — is often made from aluminum. In comparison to steel, aluminum tooling is easier to cut and it cools at a much more rapid rate, which can help reduce cycle times. Learn more about our prototype injection molding.

3D Printing

3D Printing is a very common form of prototyping. It is a fast and affordable way to produce 1 part, or a very short run of parts. There are numerous different 3D printing technologies that offer different strengths — some that are more geared for appearance/resolution where others have a lesser appearance but higher strength and durability. 3D Printing is a great way to prove out a concept prior to investing in something like an injection mold tool. Learn more about our rapid 3D printing.

Urethane & Silicone Casting

This is a manufacturing method geared for short runs of prototype or production parts. Everyone has a different quantity of which they consider prototype or production, but in general, cast urethane parts are done in quantities fewer than 100 pieces. Urethane and silicone casting is a manufacturing process that typically utilizes silicone, or RTV molds to create plastic, rubber or silicone parts. These molds generally last for 25 parts before needing to be replaced; the urethane/silicone that is injected into them to create the cast part undergoes a chemical reaction that generates a lot of heat which stresses and dries out the silicone mold. Stress to the mold is also caused by the demolding process (removal of the cast part), which is done by hand utilizing many tools such as compressed air, pry bars, plyers, and others. Learn more about our urethane casting.

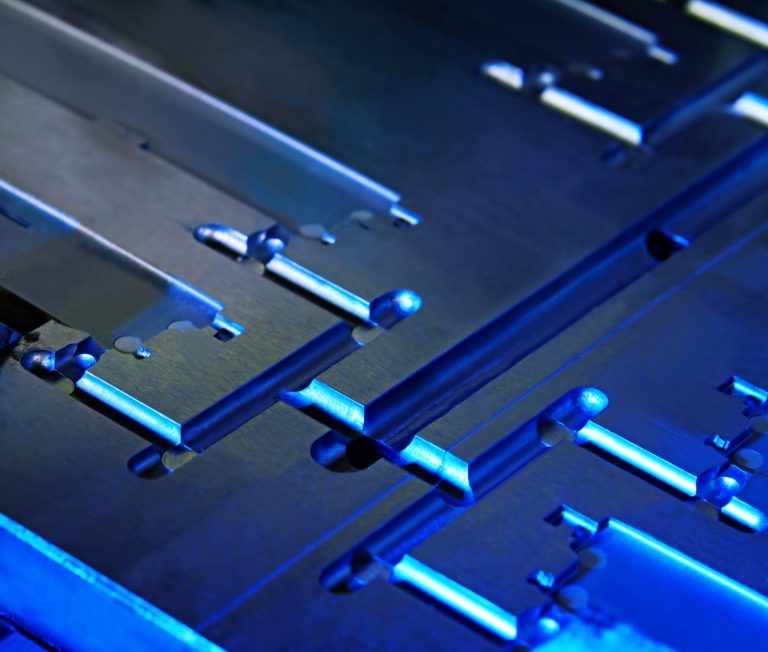

CNC Machining

CNC machining can be done in prototype or production volumes. Ston-Engineering offers CNC milling, turning and EDM machining to produce accurate parts that closely simulate final-product appearance. With advanced software to guide our CNC machines, our equipment can cut a wide variety of substrates to create flawless end results. Learn more about our CNC prototyping service.

Melt Temperature Measurement System

For Schmit customers who know how to create their own prototypes with injection molding, we now offer a melt temperature measurement kit, which provides an important key to the prototyping process. Having the ability to measure melt temperatures opens up the opportunity for customers to accurately and precisely measure temperatures when working with injecting molding. Create prototypes quickly while eliminating human error with your own Melt Temperature Measurement System Kit.

FAQs

We can accept native SolidWorks (.sldprt) files as well as solid 3D CAD models in IGES (.igs), or STEP (.stp).

Files can be uploaded here on our website, as well as attached in an email.

Yes, Ston-Engineering can provide a first article for you.

Yes, if you have a current design that needs some modifications done to it, we can work with you to get that done.