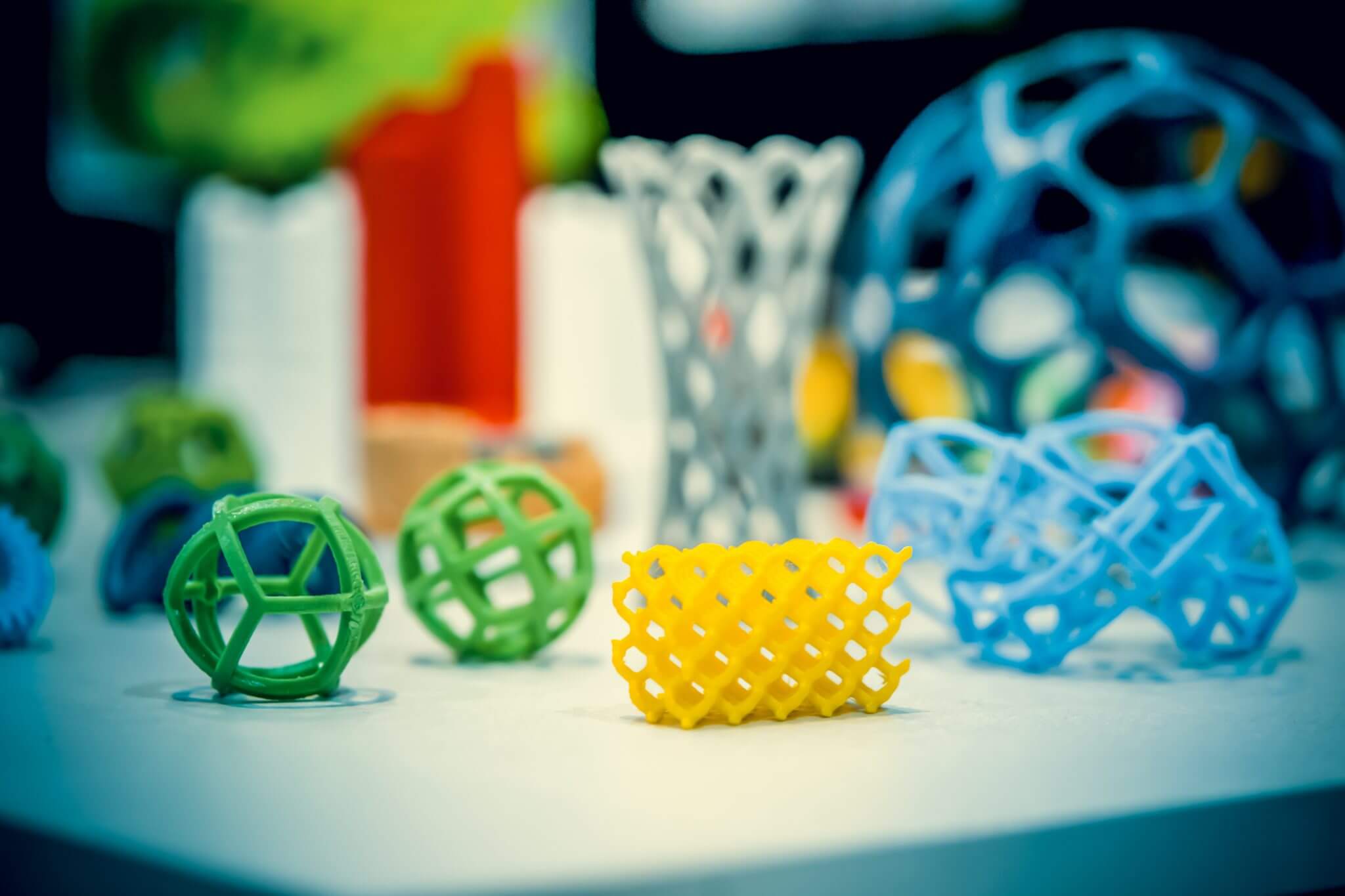

Rapid 3D Printing Solutions

Rapid 3D printing is the prototyping process of taking 3D data and turning that data into a physical model in a very short time frame. If you’re looking for 3D printing services, our group of project managers can guide you through the many rapid 3D printing processes to achieve exactly what you are looking for.

Ston-Engineering 3D printing capabilities (sizing information available in FAQ section below):

Stereolithography (SLA) 3D Printing

This uses a high-powered laser that forms a hard resin inside a container that will create the 3D shape. This process converts photosensitive liquid into a 3D shape in a layer-by-layer fashion.

This process creates a more accurate prototype than other 3D printing methods, with a higher resolution. The extreme accuracy of SLA 3D printing means it is possible to use this method for end-use, low-volume production, or for rapid prototyping. When details will make the biggest difference in your prototype, SLA 3D printing is a practical choice.

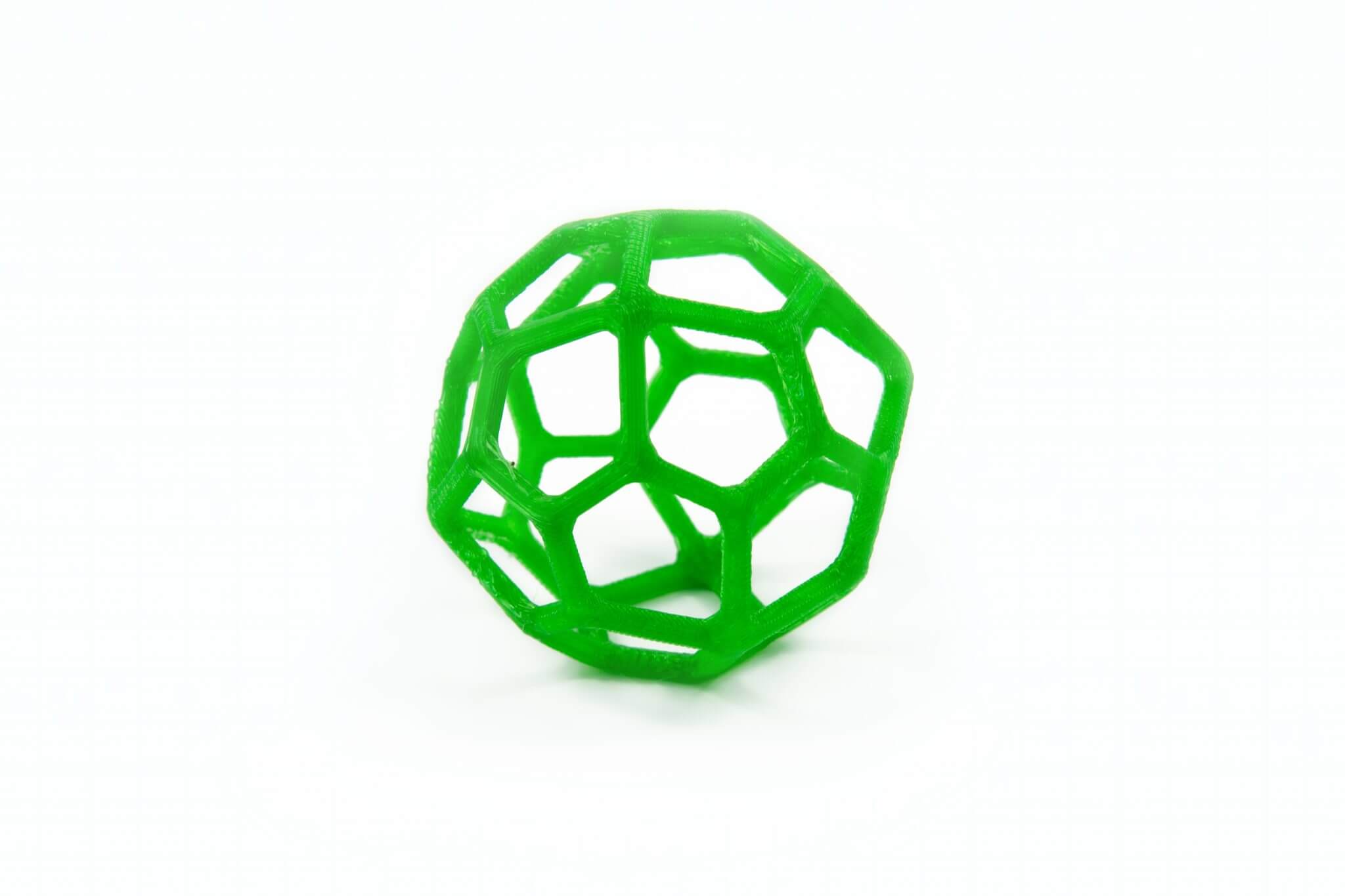

FDM 3D Printing

Fused Deposition Modeling (FDM) deposits single layers on top of one another until the desired 3D shape is created. As the equipment extrudes melted plastic filament, it creates an accurate representation of the 3D model in relatively little time. FDM 3D printed prototypes are rigid, which is important to keep in mind when you’re deciding on your 3D printing method. This process can be used with a wide range of printing materials, for both large and small-volume production.

SLS 3D Printing

Selective laser sintering (SLS) is an additive manufacturing process that uses a laser to activate sintered material to form a solid 3D object. This process provides a high degree of accuracy. We ensure that the correct amount of sintered plastic powder is fused to the prototype component by utilizing CAD files or scan data.

Polyjet 3D Printing

This is one of the most accurate types of 3D printing that creates smooth 3D parts by using liquid photopolymer. In order to produce accurate prototypes with this method, we print UV curable resin onto a build tray. The process isn’t much different from what you’d find on your typical inkjet printer. Prototyping with Polyjet 3D printing is one of the fastest and most accurate ways to bring an idea to life.

Each 3D printer has its specific advantages; please consult with one of our project managers to decide which 3D printing technology best fits your specific needs.

Advantages of 3D Printing

If you’re wondering why so many businesses are turning to 3D printing for their prototyping needs, it’s important to understand the benefits that the process provides. 3D printing offers many advantages not possible with any other prototyping method:

Rapid Turnaround

Not only do 3D printers reduce the labor required to create a prototype, they also reduce the time commitment. In every industry, time is money. You can expedite your product development with 3D printing solutions that improve efficiencies.

Accuracy

3D prototypes are built with precision. Tight tolerances are an expectation for nearly every prototype, and 3D printers reduce the chances of production errors. Your 3D printed prototype will provide an accurate representation you can use to better plan a final product or component.

Versatility

Today’s 3D printers use a variety of methods to print with a wide range of materials. This enables business owners to experiment with different printing processes and materials to identify the best option for their application. Of course, you never have to go it alone when you work with our team. We are available to direct you to the most effective printing method for your needs.

Scalable

3D printing enables businesses to turn a concept into reality at scale. By creating prototypes with precision and speed, you can focus on how your components will integrate into larger systems. Our 3D printed prototypes can help you take a strategic approach to your future business needs.

Complexity

3D printing enables our team to create prototypes with complex geometry. This makes it possible to create more intricate and detailed prototypes at a lower cost.

3D Printing Materials

3D Printing Applications

All of our customers come to us with unique challenges and opportunities, and our goal is always to make 3D printed prototypes a worthwhile service for their businesses. Wondering how we can help you? See how we use 3D printing to provide value for our customers:

Rapid Prototyping

If you need a fully functional prototype quickly, rapid prototyping through 3D printing makes it possible. No matter how intricate your design, rapid prototyping can give you a better idea of how it will work in the real world.

Concept Models

Sometimes, prototyping is a process that occurs in stages. The details of your prototype might not be decided on yet, but a concept model can provide guidance for how to move forward.

Direct Digital Manufacturing

Build discrete or customized parts in bulk with the accuracy and speed of 3D printing.

FAQs

FDM models can be built up to: 36″ x 24″ x 36″ (914mm x 610mm x 914mm). Larger models of virtually any size, can be sectioned and assembled upon completion.

SLS models can be built up to: 15″ x 13″ x 18″ (550mm x 550mm x 460mm). Larger models of virtually any size, can be sectioned and assembled upon completion.

Polyjet models can be built up to: 19.7″ x 15.7″ x 7.9″ (500mm x 400mm x 200mm).